Importance for Hot Dip Galvanizing

Importance for Hot Dip Galvanizing

Holes

Making holes only whenever is required after consulting the customer. In order to obtain the best quality for hot dip galvanizing holes are important, especially for tubes.Holes need to be present for several reasons:

- For jigging the material.

- For de-aeration of the material.

- For draining the material.

- For prevention of explosion during galvanizing.

- For releasing of the ashes during galvanizing.

When holing is not carried properly it will lead to reduction in quality with black spots and ash remains.

Welding

Welding of steel parts has a big influence on the quality of the galvanized material. The welds:

- Should be completely close because chemicals will come out after galvanizing and dissolve the zinc layer.

- Oil and fat should be removed because the will burn into the steel and causes black spots.

- Welding spatters must be avoided.

- Welds and the surrounding areas should be cleaned afterwards by grinding.

- Proper none reactive electrode should be used to avoid thick welds.

Steel composition

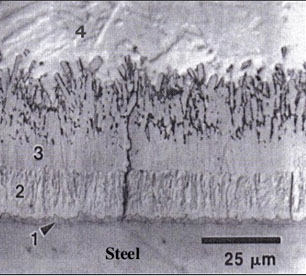

The percentages of elements in the steel, which cause an out grown zinc-layer has influence on the formation of the alloy layer of Zinc (Zn) and Iron (Fe) as shown in the mentioned microscopic photographs. The outerappearance of the layer varies from bright and shining till dark and gray like a spider web structure:

- Si between 0,05-0,12%w/w, or higher than 0,25%w/w

- P > 0,045%w/w.

- Si + 2,5 x P > 0,09, when Si <0,03%w/w.

- Si + 2,5 x P > 0,2%w/w ('French-standard').

- Si ± 0,02%w/w and an Al-percentage 0,045%w/w.

This effect can partly be suppressed by using alloy-elements in the zinc bath.